Single Wall Heat Shrink Tubing

The ultra thin wall heat shrinkable tubing is thinner than the general purpose G5 tubing. In addition to the same application as G5, its ultra thin wall thickness has lower shrink temperature and faster shrinkage speed. It is used for the connector protection in the high density space and reduces the damage to temperature-sensitive components when heating.

Powered by Froala Editor

Powered by Froala Editor

FEATURES

• Shrink ratio: 2:1

• Very flexible, high flame retardant

• Low shrink temperature and rapid shrinkage

• Excellent physical, chemical and electrical performance

• Compliance with RoHS

Powered by Froala Editor

Powered by Froala Editor

TYPICAL APPLICATIONS

Material data: Polyolefin

Continuous operating temperature: -55˚C~125˚C

Minimum shrink temperature: 60˚C

Full recovery temperature: Above 110˚C

Approvals: UL224 File no.E255532,125˚C VW-1 300V

Standard color: Black (Special sizes, and cut pieces are available on request)

Powered by Froala Editor

TECHNICAL DATA

| Property | Specification requirement | Test method | Test result |

| Longitudinal change | -10%~10% | ASTM D2671 | Pass |

| Tensile strength | ≥10.3MPa | ASTM D2671 | ≥11.3MPa |

| Elongation at break | ≥200% | ASTM D2671 | ≥400% |

| Tensile strength after aging | 70% of initial value | ASTM D2671 (158˚C/168 hrs) | ≥80% |

| Elongation at break after aging | ≥100% | ASTM D2671 (158˚C/168 hrs) | ≥200% |

| Heat shock | No cracking | ASTM D2671 (200˚C/4 hrs) | No cracking |

| Low temperature flexibility | No cracking | ASTM D2671 (-30˚C/1 hr) | No cracking |

| Dielectric voltage withstand | AC2500V/60S No breakdown | ASTM D2671 | No breakdown |

| Volume resistivity | ≥10144Ω‧cm | ASTM D2671 | ≥10144Ω‧cm |

| Dielectric strength | ≥19.7kV/mm | ASTM D2671 | 22 kV/mm |

| Flammability | VW-1 | UL224 | Pass |

Powered by Froala Editor

Powered by Froala Editor

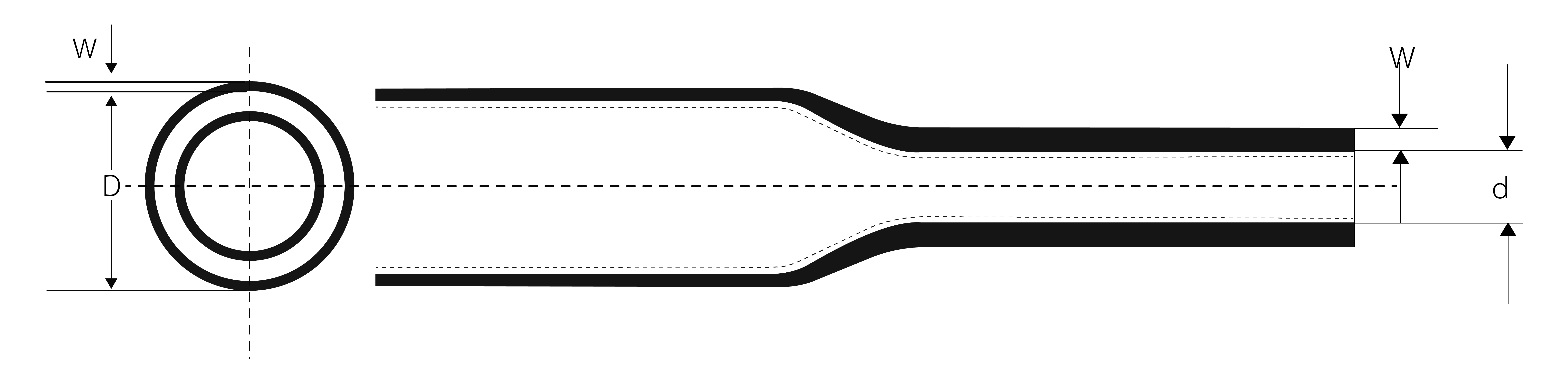

DIMENSIONS

| Part no. | Size (mm) | As supplied(mm) | After unrestricted shrinkage(mm) | Standard length (meter) | ||

| ID.(D) | W.T(W) | ID(Max) (d) | WT(Min) (w) | |||

| G5CB-0010 | 1.0 | 1.4±0.2 | 0.13±0.5 | 0.7 | 0.20±0.1 | 200 |

| G5CB-0015 | 1.5 | 1.9±0.2 | 0.13±0.5 | 0.85 | 0.20±0.1 | 200 |

| G5CB-0020 | 2.0 | 2.4±0.2 | 0.13±0.5 | 1.0 | 0.22±0.1 | 200 |

| G5CB-0025 | 2.5 | 2.8±0.3 | 0.13±0.5 | 1.3 | 0.25±0.1 | 200 |

| G5CB-0030 | 3.0 | 3.4±0.3 | 0.13±0.5 | 1.5 | 0.28±0.1 | 200 |

| G5CB-0035 | 3.5 | 3.9±0.3 | 0.13±0.5 | 1.75 | 0.25 | 200 |

| G5CB-0040 | 4.0 | 4.4±0.3 | 0.15±0.5 | 2.0 | 0.25 | 200 |

| G5CB-0045 | 4.5 | 5.0±0.3 | 0.15±0.5 | 2.25 | 0.25 | 100 |

| G5CB-0050 | 5.0 | 5.5±0.3 | 0.15±0.5 | 2.5 | 0.25 | 100 |

| G5CB-0060 | 6.0 | 6.5±0.3 | 0.15±0.5 | 3.0 | 0.28 | 100 |

| G5CB-0070 | 7.0 | 7.5±0.3 | 0.15±0.5 | 3.5 | 0.28 | 100 |

| G5CB-0080 | 8.0 | 8.6±0.4 | 0.15±0.5 | 4.0 | 0.28 | 100 |

| G5CB-0090 | 9.0 | 9.6±0.4 | 0.15±0.5 | 4.5 | 0.28 | 100 |

| G5CB-0100 | 10.0 | 10.6±0.4 | 0.15±0.5 | 5.0 | 0.28 | 100 |

| G5CB-0110 | 11.0 | 11.6±0.4 | 0.18±0.5 | 5.5 | 0.28 | 100 |

| G5CB-0120 | 12.0 | 12.6±0.4 | 0.20±0.5 | 6.0 | 0.28 | 100 |

| G5CB-0130 | 13.0 | 13.6±0.4 | 0.20±0.5 | 6.5 | 0.30 | 100 |

| G5CB-0140 | 14.0 | 14.6±0.4 | 0.20±0.5 | 7.0 | 0.30 | 100 |

| G5CB-0150 | 15.0 | 15.6±0.5 | 0.20±0.5 | 7.5 | 0.32 | 100 |

| G5CB-0160 | 16.0 | 16.6±0.5 | 0.20±0.5 | 8.0 | 0.32 | 100 |

Powered by Froala Editor

Powered by Froala Editor