Dual Wall Adhesive-Lined Polyolefin Tubing

Specially designed to insulate and seal automotive wire splices and components in an under-the-hood automotive environment. Specially formulated to function at an extended temperature range.

Powered by Froala Editor

FEATURES

• 4:1 shrink ratio allows a few sizes to cover a wide range of splice and component diameters

• Flame-retardant and mechanically tough, the tubing provides strain relief and abrasion protection of wire splices, terminals, and other components

• Thick adhesive liner forms an effective barrier against fluids and moisture and performs well at an extended temperature range

• RoHS/ELV compliant

Powered by Froala Editor

TYPICAL APPLICATIONS

Material data: Polyolefin

Operating temperature: -40˚C~150˚C

Minimum shrink temperature: 110˚C

Minimum full recovery temperature: 135˚C

Standard color: Black and clear

Powered by Froala Editor

Powered by Froala Editor

TECHNICAL DATA

| Property | Unit | Performance requirements | Testing method | Test result | |

| Longitudinal change | % | 0 to -100 | ASTM D2671/ UL 224 | 0 to -5 | |

| Tensile strength | MPa | ≥10.4 | ASTM D2671 | 15.65 | |

| Breakage elongation | % | ≥200 | ASTM D2671 | 318.48 | |

| Cold impact: 4H, -40±2°C | \ | No crack | UL 224 | Pass | |

| Heat Shock: 4H, 250±3°C (only jacket) | \ | No drip , no flow, no crack | UL 224 | Pass | |

| Heat aging (only jacket) 168H, 175±2°C | Tensile strength | MPa | ≥7.3 | UL 224 | 13.85 |

| Breakage elongation | % | ≥100 | UL 224 | 253.82 | |

| Volume resistivity | Ω.cm | ≥1x1012 | ASTM D2671 | 1x1013 | |

| Copper corrosion | / | 158℃, 168h, Pass | UL 224 | Non corrosive | |

| Water absorption | % | ≤1.0% | ASTM D570 | 0.5 | |

Powered by Froala Editor

Powered by Froala Editor

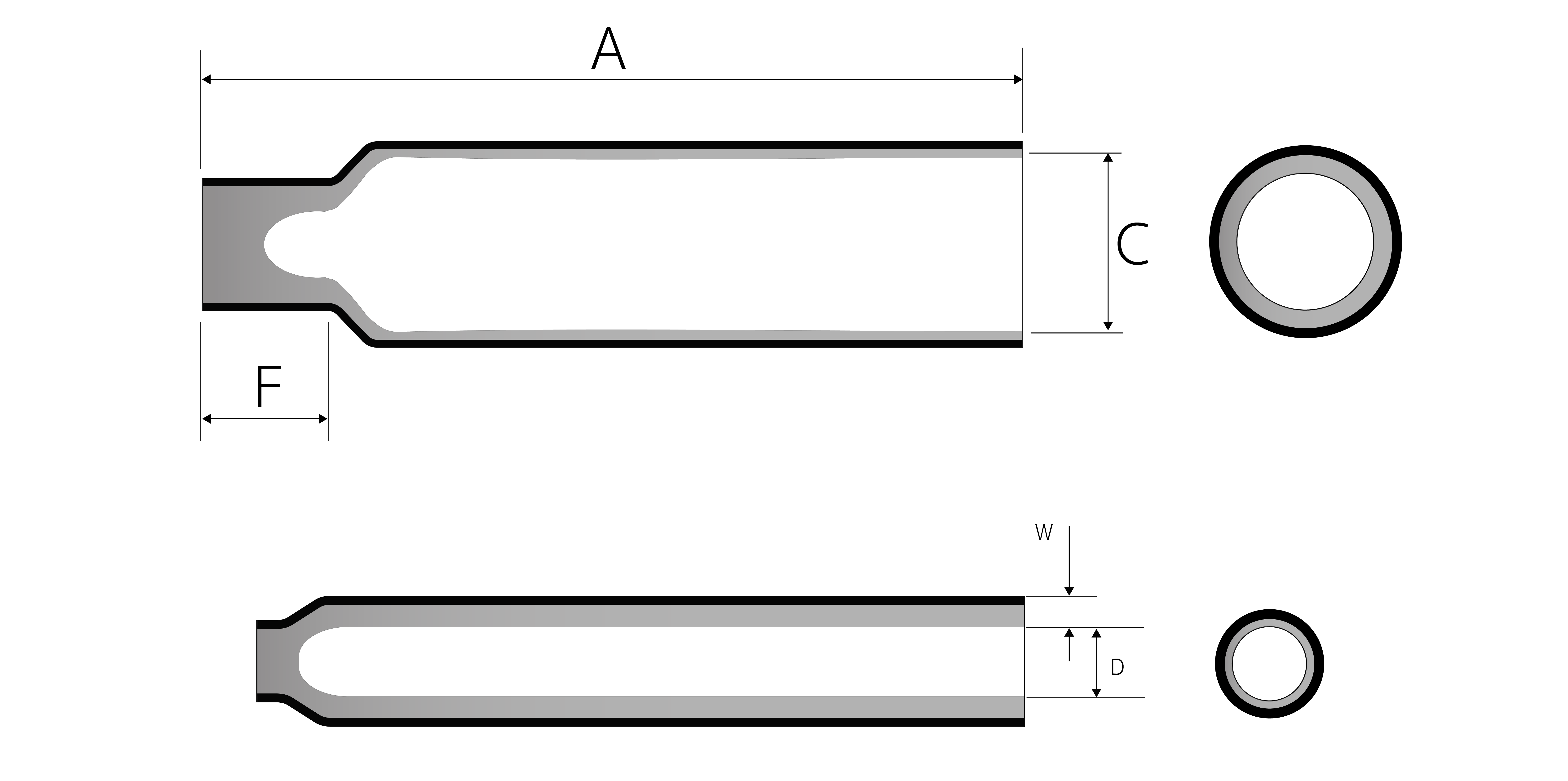

DIMENSIONS

| Part no. | Size(mm) | A(mm) | As supplied(mm) | After unrestricted shrinkage(mm) | ||

| ID min (C) | Preshrink seal length min(F) | ID Max (D) | Total thickness (W) | |||

| S-CAPS-0032 | 3.2 | 25 | 3.2 | 4.0 | ≤1.00 | 1.00±0.10 |

| S-CAPS-0057 | 5.75 | 30 | 5.75 | 4.0 | ≤1.27 | 1.50±0.15 |

| S-CAPS-0074 | 7.40 | 35 | 7.40 | 5.0 | ≤1.65 | 1.80±0.20 |

| S-CAPS-0108 | 10.8 | 45 | 10.8 | 5.0 | ≤2.40 | 2.10±0.30 |

Powered by Froala Editor

Powered by Froala Editor