Medium Wall Adhesive-Lined Polyolefin Tubing

Medium wall adhesive-lined heat shrink tubing suitable for a variety of low voltage electrical and mechanical application, where lighter weight and greater flexibility are important.

Powered by Froala Editor

FEATURES

• Shrink ratio: 3:1

• Flame-retardant

• Seal and protect cable splice and terminations

• High resistance to impact and abrasion

• Resists puncture and abrasion damage

• Resists acids and alkalies

• Bonds to a wide variety of substrates

• Thermoplastic adhesive liner for complete environmental

• Protection and insulation

• UV resistant

• Rated voltage: 1000V

• RoHS compliant

Powered by Froala Editor

Powered by Froala Editor

TYPICAL APPLICATIONS

Material data: Polyolefin

Operating temperature: -45˚C~+125˚C

Minimum shrink temperature: 70˚C

Minimum full recovery temperature: 125˚C

Standard color: Black (Other color available upon request)

Powered by Froala Editor

TECHNICAL DATA

| Property | Test method | Test result |

| Tensile strength (MPa) | ASTM D2671 | ≥10.4 |

| Elongation (%) | ASTM D2671 | ≥200 |

| Tensile strength after aging (MPa) | UL224 158˚C x168hrs | ≥7.3 |

| Elongation at break after aging (%) | UL224 158˚C x168hrs | ≥100 |

| Longitudinal shrink ratio (%) | UL 224 | ≤±10% |

| Dielectric Strength (KV/mm) | IEC 60243 | ≥15 |

| Volume resistance (Ω·cm) | IEC 60093 | ≥1x1014 |

| Flame redundancy | SAE-AMS-DTL-23053/5 | Self-extinguishing in 30 seconds |

Hot melting adhesive

| Property | Test method | Test result |

| Water absorption | ASTM-D570 | <0.2% |

| Vicat softening point | ASTM-E28 | 95℃ |

| Peel strength (PE) | ASTM-D1000 | 120N/25mm |

| Peel strength (AL) | ASTM-D1000 | 80N/25mm |

Powered by Froala Editor

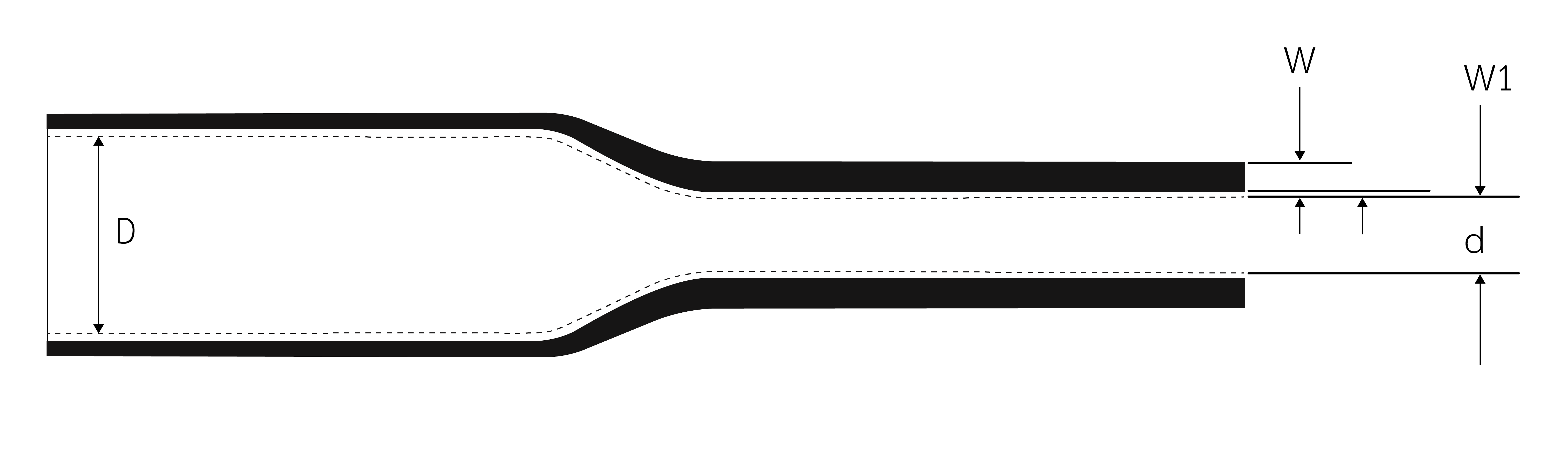

DIMENSIONS

Part no. | Size (mm) | As supplied(mm) | After recovered(mm) | Standard package (m/pcs) | |||

ID(D) | ID(d) | Out layer W.T | Adhessive thickness(w1) | Total W.T.(w) | |||

| RSM-FR-0120 | 12.0 | ≥12.0 | ≤3.0 | 1.40±0.20 | 0.35±0.15 | 1.75±0.30 | 1.22 |

| RSM-FR-0160 | 16.0 | ≥16.0 | ≤5.0 | 1.50±0.20 | 0.40±0.15 | 1.90±0.30 | 1.22 |

| RSM-FR-0190 | 19.0 | ≥19.0 | ≤5.6 | 2.00±0.20 | 0.45±0.20 | 2.45±0.35 | 1.22 |

| RSM-FR-0220 | 22.0 | ≥22.0 | ≤6.0 | 2.00±0.25 | 0.45±0.20 | 2.45±0.40 | 1.22 |

| RSM-FR-0280 | 28.0 | ≥28.0 | ≤9.0 | 2.00±0.25 | 0.50±0.20 | 2.60±0.40 | 1.22 |

| RSM-FR-0330 | 33.0 | ≥33.0 | ≤8.0 | 2.20±0.25 | 0.78±0.20 | 2.70±0.40 | 1.22 |

| RSM-FR-0400 | 40.0 | ≥40.0 | ≤12.0 | 2.20±0.25 | 0.50±0.20 | 2.70±0.40 | 1.22 |

| RSM-FR-0440 | 44.0 | ≥44.0 | ≤14.0 | 2.20±0.25 | 0.50±0.20 | 2.70±0.40 | 1.22 |

| RSM-FR-0550 | 55.0 | ≥55.0 | ≤16.0 | 2.30±0.25 | 0.50±0.20 | 2.80±0.45 | 1.22 |

| RSM-FR-0650 | 65.0 | ≥65.0 | ≤19.0 | 2.50±0.25 | 0.50±0.20 | 3.00±0.45 | 1.22 |

| RSM-FR-0750 | 75.0 | ≥75.0 | ≤22.0 | 2.60±0.35 | 0.50±0.20 | 3.00±0.45 | 1.22 |

| RSM-FR-0850 | 85.0 | ≥85.0 | ≤25.0 | 2.80±0.35 | 0.50±0.20 | 3.30±0.45 | 1.22 |

| RSM-FR-0950 | 95.0 | ≥95.0 | ≤29.0 | 3.10±0.45 | 0.60±0.20 | 3.70±0.50 | 1.22 |

| RSM-FR-1150 | 115.0 | ≥115.0 | ≤34.0 | 3.10±0.45 | 0.60±0.20 | 3.70±0.50 | 1.22 |

| RSM-FR-1400 | 140.0 | ≥140.0 | ≤42.0 | 3.10±0.45 | 0.60±0.20 | 3.70±0.50 | 1.22 |

| RSM-FR-1600 | 160.0 | ≥160.0 | ≤48.0 | 3.10±0.45 | 0.60±0.20 | 3.70±0.50 | 1.22 |

| RSM-FR-1800 | 180.0 | ≥180.0 | ≤58.0 | 3.10±0.45 | 0.60±0.20 | 3.70±0.50 | 1.22 |

| RSM-FR-2000 | 200.0 | ≥200.0 | ≤60.0 | 3.10±0.45 | 0.60±0.20 | 3.70±0.50 | 1.22 |

| RSM-FR-2350 | 235.0 | ≥235.0 | ≤69.0 | 3.10±0.45 | 0.60±0.20 | 3.70±0.50 | 1.22 |

Powered by Froala Editor

Powered by Froala Editor