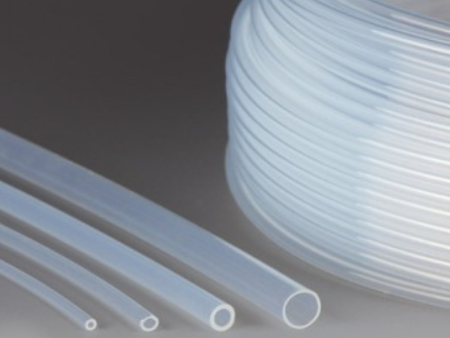

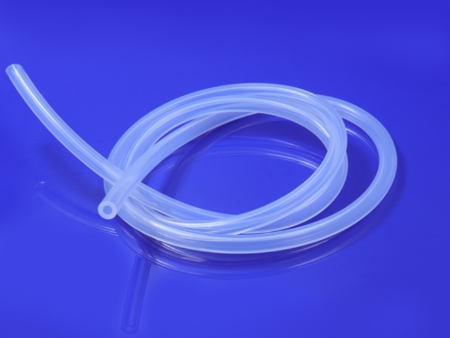

Heat Temperature Tube

PTFE tubing is of high temperature (260℃) resistance, corrosion resistance, excellence insulation and mechanical strength properties. The tubing is being applied widely in industries of electrical, computer, chemical, high temperature areas, aerospace, military and transmission system etc.

Powered by Froala Editor

FEATURES

• Excellent flammability

• High temperature resistant to 260℃

• Excellent physical properties and chemical resistance.

• RoHS and REACH compliant.

Powered by Froala Editor

TYPICAL APPLICATIONS

Material data: PTFE

Operating temperature: -80˚C~260˚C

Standard color: Black, white, red, yellow and blue (Other colors are available upon request)

Powered by Froala Editor

TECHNICAL DATA

| Property | Test method | Unit | Test result |

| Specific gravity | ASTM D972 | g/cm3 | 2.16 |

| Tensile strength | ASTM D638 | MPa | 24.5 |

| Ultimate elongation | ASTM D638 | % | 350 |

| Flexural modulus | ASTM D790 | MPa | 490 |

| Impact strength | ASTM D256+23℃-54℃j/m | / | No break, 107 |

| Hardness | ASTM D2240 | Shore D | 55 |

| Coefficient of dynamic friction | / | / | 0.1 |

| Melting point | / | ℃ | 327 |

| Service temperature 20000h with 50% retention of ultimate elongation | / | ℃ | 260 |

| Inflammability | UL 224 | / | VW-1 |

| Dielectric constant at 103-106Hz | ASTM D150 | / | 2.1 |

| Dissipation factor at 106Hz | ASTM D150 | / | 0.0002 |

| Arc resistance | ASTM D495(Stainless steel electrodes) | S | >300 |

| Volume resistivity | ASTM D257 | Ω·cm | >1018 |

| Weather resistance | “Weather-o-meter”(2000h) | / | No break |

| Solvent resistance | ASTM D543 | / | Excellent |

| Chemical resistance | ASTM D543 | / | Excellent |

Powered by Froala Editor

DIMENSIONS

| Size | Inner diameter(ID) (mm) | Outside diamenter(OD) (mm) | ||||

| AWG | MIN | NOR | MAX | S-TYPE | T-TYPE | L-TYPE |

| 30 | 0.25 | 0.30 | 0.38 | 0.76 | 0.76 | 0.60 |

| 28 | 0.33 | 0.38 | 0.46 | 0.48 | 0.84 | 0.68 |

| 26 | 0.41 | 0.46 | 0.53 | 0.92 | 0.92 | 0.76 |

| 24 | 0.51 | 0.56 | 0.66 | 1.16 | 1.06 | 0.86 |

| 23 | 0.58 | 0.66 | 0.74 | 1.26 | 1.16 | 0.96 |

| 22 | 0.66 | 0.71 | 0.81 | 1.31 | 1.21 | 1.01 |

| 21 | 0.74 | 0.81 | 0.89 | 1.41 | 1.31 | 1.11 |

| 20 | 0.81 | 0.86 | 0.97 | 1.66 | 1.46 | 1.16 |

| 19 | 0.91 | 0.96 | 1.01 | 1.76 | 1.56 | 1.26 |

| 18 | 1.01 | 1.07 | 1.17 | 1.87 | 1.67 | 1.37 |

| 17 | 1.14 | 1.19 | 1.32 | 1.99 | 1.79 | 1.49 |

| 16 | 1.29 | 1.34 | 1.47 | 2.14 | 1.94 | 1.64 |

| 15 | 1.45 | 1.50 | 1.62 | 2.30 | 2.10 | 1.80 |

| 14 | 1.62 | 1.68 | 1.83 | 2.48 | 2.28 | 2.08 |

| 13 | 1.83 | 1.93 | 2.05 | 2.73 | 2.53 | 2.33 |

| 12 | 2.05 | 2.16 | 2.31 | 2.96 | 2.77 | 2.56 |

| 11 | 2.31 | 2.41 | 2.57 | 3.21 | 3.01 | 2.81 |

| 10 | 2.59 | 2.69 | 2.84 | 3.49 | 3.29 | 3.09 |

| 9 | 5.90 | 3.00 | 3.10 | 4.00 | 3.76 | 3.40 |

| 8 | 3.28 | 3.38 | 3.53 | 4.38 | 4.14 | 3.78 |

| 7 | 3.65 | 3.76 | 3.94 | 4.76 | 4.52 | 4.16 |

| 6 | 4.11 | 4.22 | 4.41 | 5.22 | 4.98 | 4.72 |

| 5 | 4.62 | 4.72 | 4.95 | 5.72 | 5.48 | 5.22 |

| 4 | 5.18 | 5.28 | 5.53 | 6.28 | 6.04 | 5.78 |

| 3 | 5.81 | 5.94 | 6.20 | 6.94 | 6.70 | 6.44 |

| 2 | 6.55 | 6.68 | 6.93 | 7.68 | 7.44 | 7.18 |

| 1 | 7.34 | 7.46 | 7.75 | 8.46 | 8.22 | 7.96 |

| 0 | 8.26 | 8.38 | 8.69 | 9.38 | 9.14 | 8.88 |

Powered by Froala Editor

Powered by Froala Editor