Dual Wall Adhesive-Lined Polyolefin Tubing

Dual-wall adhesive-lined heat shrinkable tubing is made by co-extrusion of excellent polyolefin compounds and hot-melt adhesive. It is used for water-proofing and insulation protection of wire and cable and wire harnesses, and connector-to-cable transitions. It is typically used in the insulation and sealing of electrical and electronic components, automotive and communication industry. Electrical and electronic components Refrigerator copper &aluminum, automotive and communication industry.

Powered by Froala Editor

FEATURES

• Shrink ratio: 3:1

• Good hot-melt adhesive and high expansion ratio to provide good sealing protection.

• EVA hot melt adhesive for cooper and aluminium.

• Environmental sealing and protection of electrical applications.

• Flexible, flame retardant

• RoHS and REACH compliant

Powered by Froala Editor

TYPICAL APPLICATIONS

Material data: Polyolefin

Operating temperature: -40°C~125°C

Minimum shrink temperature: 110°C

Minimum fully recovery temperature: 150°C

Standard color: Black, white, red, yellow, blue, green, grey (Other colors are available upon request)

Powered by Froala Editor

TECHNICAL DATA

| Property | Requirement | Test method | Test result |

| Longitudinal shrinkage | ≤10% | ASTM D 2671 | ≤5% |

| Tensile strength | ≥10.4 MPa | ASTM D 2671 | ≥14 MPa |

| Elongation at break | 200% min. | ASTM D 2671 | ≥400% |

| Tensile strength after ageing (158℃,168hrs) | ≥7.3 MPa | ASTM D 2671 | ≥13 MPa |

| 100% min. | ASTM D 2671 | ≥300% | |

| Heat shock (200℃,4hrs) | No crack | ASTM D 2671 | No crack |

| Low-temperature flexibility (-55℃,4hrs) | No crack | ASTM D 2671 | No crack |

| Dielectric voltage withstand | 2500V,60sec, no breakdown | ASTM D 2671 | No breakdown |

| Volume resistivity | ≥1012 Ω•cm | ASTM D 876 | ≥1014Ω·cm |

| Flammability | VW-1 | UL 224 | Pass |

Powered by Froala Editor

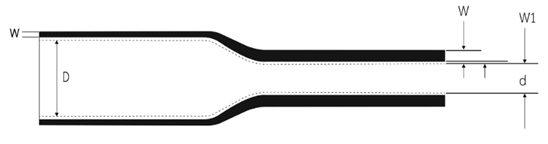

DIMENSIONS

| Part no. | Size(mm) | As supplied(mm) | After shrinkage(mm) | Standard package(m/pcs) | |||

| ID(min) (D) | W.T(W) | ID(max) (d) | Total W.T(w) | Adhesive thickness(w1) | |||

| SDW-(3CA) | 10.0 | ≥10.0 | 0.55 | ≤3.00 | 1.35±0.25 | 0.6 | 1.22 |

| SDW-(3CA) | 12.7 | ≥13.0 | 0.55 | ≤4.00 | 1.35±0.25 | 0.6 | 1.22 |

| SDW-(3CA) | 15.0 | ≥15.0 | 0.60 | ≤5.00 | 1.55±0.25 | 0.6 | 1.22 |

Powered by Froala Editor