Single Wall Heat Shrink Tubing

This specification applies to wire connection, disposal of wire termination, sign of the wire bind, insulate protection of resistance and capacitance, surface protection of sport equipment and the steel frame, rust-proof and corrosion-proof of relative products, wire protection and other.

Powered by Froala Editor

FEATURES

• Shrink ratio: 3:1

• Longitudinal shrink ratio ≤±8%

• Flame retardant(colors only)

• Resistant to common solvent liquid

• Excellent physical, chemical, and electrical performance

• Compliance with RoHS

Powered by Froala Editor

Powered by Froala Editor

TYPICAL APPLICATIONS

Material data: Polyolefin

Operating temperature: -55˚C~135˚C

Minimum shrink temperature: 70˚C

Minimum full recovery temperature: 120˚C

Approvals: UL224; AMS-DTL-23053/5 class1

Standard color: Black, white, red, blue, yellow, and green (Other colors, special sizes, and cut pieces are available on request)

Powered by Froala Editor

TECHNICAL DATA

| Property | Test method | Test result | |

| Physical | Tensile strength/ MPa | ASTM D638 | ≥10.4 |

| Elongation/ % | ASTM D638 | ≥200 | |

| Tensile strength after aging/ MPa | 175˚C/168hr | ≥7.3 | |

| Elongation after aging/ % | 175˚C/168hr | ≥100 | |

| Heat Shock | 250˚C/4hrs | No viscidity / No cracking | |

| Cold Blend | -55˚C/1hr | No cracking | |

| Electrical | Dielectric withstand | 2500V 1 Min | Without breakdown |

| Dielectric strength/ KV/mm | ASTM D2671 | ≥15 | |

| Volume resistance/ Ω·cm | ASTM D638 | ≥1x1014 | |

| Chemical | Copper stability | UL224;175˚C/168hrs | Pass |

| Anti corrosion | UL224;175˚C/168hrs | Pass | |

| Flammability | ASTM D2671 C | Pass | |

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

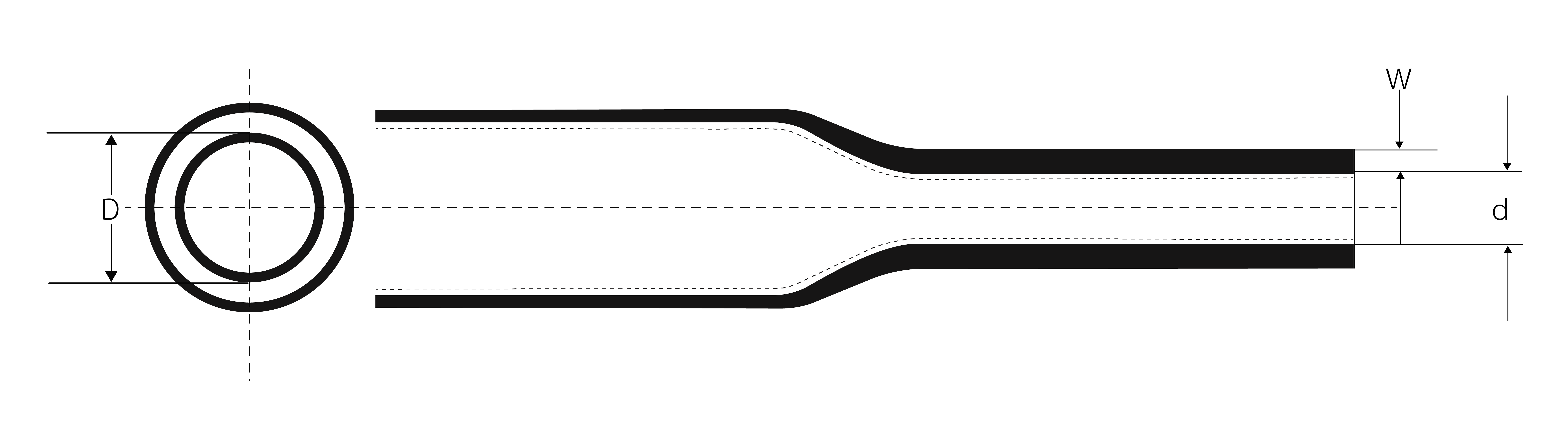

DIMENSIONS

| Part no. | Size(mm) | As supplied | After shrinkage(mm) | Standard lenght (meter) | Application range (mm) | |

| ID(D) | ID(d) | W.T(w) | ||||

| SHT135-3X0015 | 1.5 | ≥1.50 | ≤0.5 | 0.45±0.10 | 200 | 0.70~1.30 |

| SHT135-3X0030 | 3.0 | ≥3.00 | ≤1.0 | 0.51±0.10 | 200 | 1.20~2.80 |

| SHT135-3X0045 | 4.5 | ≥4.50 | ≤1.5 | 0.60±0.10 | 200 | 1.70~4.30 |

| SHT135-3X0060 | 6.0 | ≥6.00 | ≤2.0 | 0.65±0.10 | 200 | 2.20~5.80 |

| SHT135-3X0090 | 9.0 | ≥9.00 | ≤3.0 | 0.75±0.15 | 100 | 3.20~8.70 |

| SHT135-3X0120 | 12.0 | ≥12.0 | ≤4.0 | 0.80±0.15 | 100 | 4.20~11.8 |

| SHT135-3X0150 | 15.0 | ≥15.0 | ≤5.0 | 0.85±0.15 | 100 | 5.20~14.8 |

| SHT135-3X0180 | 18.0 | ≥18.0 | ≤6.0 | 1.00±0.20 | 100 | 6.20~17.7 |

| SHT135-3X0240 | 24.0 | ≥24.0 | ≤8.0 | 1.15±0.20 | 100 | 8.20~23.5 |

| SHT135-3X0300 | 30.0 | ≥30.0 | ≤10.0 | 1.50±0.20 | 50 | 10.2~29.0 |

| SHT135-3X0390 | 39.0 | ≥39.0 | ≤13.0 | 2.50±0.20 | 50 | 13.2~38.0 |

| SHT135-3X0500 | 50.0 | ≥50.0 | ≤16.0 | 2.60±0.20 | 50 | 16.3~48.0 |

| SHT135-3X0600 | 60.0 | ≥60.0 | ≤20.0 | 2.60±0.20 | 25 | 20.5~56.0 |

| SHT135-3X0700 | 70.0 | ≥70.0 | ≤23.0 | 2.60±0.20 | 25 | 23.5~66.0 |

| SHT135-3X0800 | 80.0 | ≥80.0 | ≤26.0 | 2.60±0.20 | 25 | 26.5~75.0 |

| SHT135-3X0900 | 90.0 | ≥90.0 | ≤30.0 | 2.60±0.20 | 25 | 31.0~80.0 |

| SHT135-3X1000 | 100.0 | ≥100.0 | ≤33.0 | 2.60±0.20 | 25 | 34.0~90.0 |

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor