High Temperature Heat Shrinkable Tube

FEP heat shrinkable tubing is made of FEP with excellent 200℃ high-temperature performance, chemical resistance, high insulation and excellent mechanical properties. FEP has excellent abrasion resistance and excellent clarity. Designed to provide insulation and mechanical protection in severe chemical and thermal environments. Widely used in electronic, aerospace, military and communication fields.

Powered by Froala Editor

FEATURES

• Shrink ratio: 1.3:1

• Excellent clarity

• High flame resistance

• High temperature resistant to 200℃

• Superior physical and chemical properties

• RoHS and REACH compliant

Powered by Froala Editor

Powered by Froala Editor

TYPICAL APPLICATIONS

Material data: FEP

Operating temperature: -65˚C~200˚C

Minimum fully recovery temperature: 210℃

Standard color: Clear

Powered by Froala Editor

TECHNICAL DATA

| Property | Requirement | Test method | Test result |

| Longitudinal shrinkage | ≤5% | ASTM D 2671 | ≤3% |

| Tensile strength | ≥13.8 MPa | ASTM D 2671 | ≥19 MPa |

| Elongation at break | ≥150% | ASTM D 2671 | ≥250% |

| Tensile strength after ageing(232℃, 168hrs) | ≥9.7 MPa | ASTM D 2671 | ≥14 MPa |

| Elongation after ageing (200℃, 168hrs) | ≥100% | ASTM D 2671 | ≥250% |

| Heat shock (260℃, 4hrs) | No crack | ASTM D 2671 | No crack |

| Low temperature flexibility(-65℃, 4hrs) | No crack | ASTM D 2671 | No crack |

| Dielectric voltage withstand | 2500V, 60sec, No breakdown | ASTM D 2671 | Pass |

| Volume resistivity | 1015Ω·cm min. | ASTM D 876 | ≥1016Ω·cm |

| Corrosion | No corrosion | ASTM D 2671 | No corrosion |

| Flammability | VW-1 | UL 224 | Pass |

| Dielectric constant | / | / | 2.1 |

| Friction coefficient | / | / | 0.2-0.3 |

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

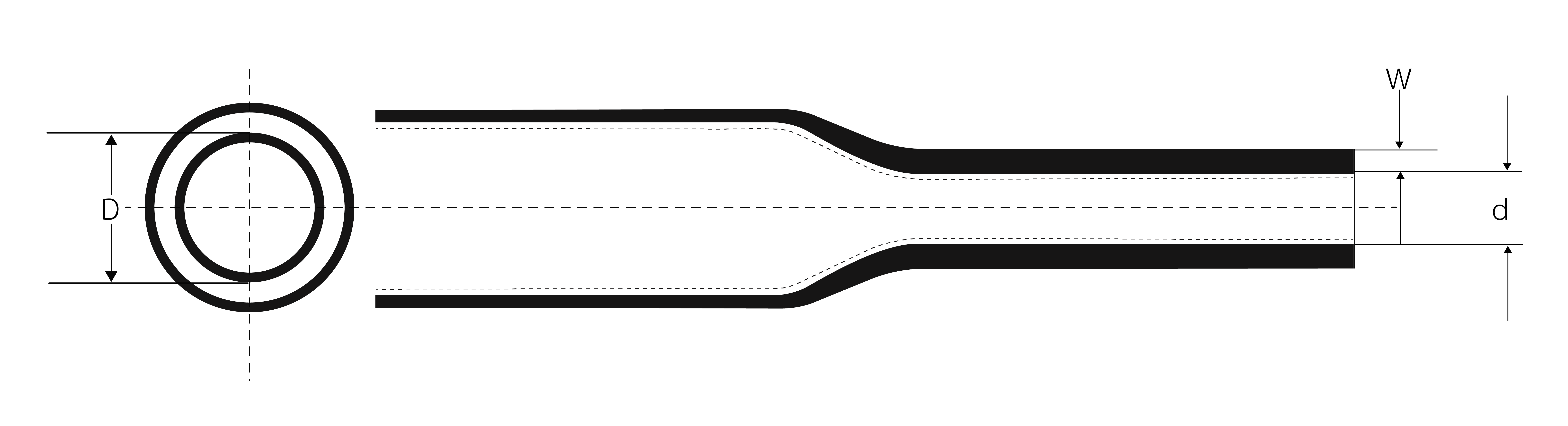

DIMENSIONS

Part no. | Size(mm) | As supplied(mm) | After recovered(mm) | Standard length (meter) | |

I.D(D) | ID(d) | W.T(w) | |||

FEP200-0010 | 1.0 | 1.0±0.15 | 0.75 | 0.2-0.3 | 1 |

FEP200-0012 | 1.2 | 1.2±0.15 | 0.9 | 0.2-0.3 | 1 |

FEP200-0016 | 1.6 | 1.6±0.2 | 1.2 | 0.2-0.3 | 1 |

FEP200-0024 | 2.4 | 2.4±0.2 | 1.9 | 0.2-0.3 | 1 |

FEP200-0032 | 3.2 | 3.2±0.2 | 2.5 | 0.2-0.3 | 1 |

FEP200-0048 | 4.8 | 4.8±0.2 | 3.5 | 0.2-0.3 | 1 |

FEP200-0057 | 5.72 | 5.72±0.2 | 4.5 | 0.25-0.3 | 1 |

FEP200-0094 | 9.4 | 9.4±0.2 | 7.2 | 0.25-0.3 | 1 |

FEP200-0100 | 10.0 | 10.0±0.2 | 8.5 | 0.3-0.4 | 1 |

FEP200-0127 | 12.7 | 12.7±0.2 | 9.5 | 0.3-0.4 | 1 |

FEP200-0160 | 16.0 | 16.0±0.2 | 12.3 | 0.3-0.4 | 1 |

FEP200-0180 | 18.0 | 18.0±0.2 | 13.8 | 0.3-0.4 | 1 |

FEP200-0190 | 19.0 | 19.0±0.2 | 14.6 | 0.3-0.4 | 1 |

FEP200-0200 | 20.0 | 20.0±0.2 | 15.4 | 0.3-0.4 | 1 |

FEP200-0220 | 22.0 | 22.0±0.2 | 17.0 | 0.3-0.4 | 1 |

FEP200-0250 | 25.0 | 25.0±0.2 | 19.0 | 0.4-0.5 | 1 |

FEP200-0280 | 28.0 | 28.0±0.2 | 21.6 | 0.4-0.5 | 1 |

FEP200-0300 | 30.0 | 30.0±0.2 | 23.1 | 0.4-0.5 | 1 |

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor