The correct way to use heat shrink tubing

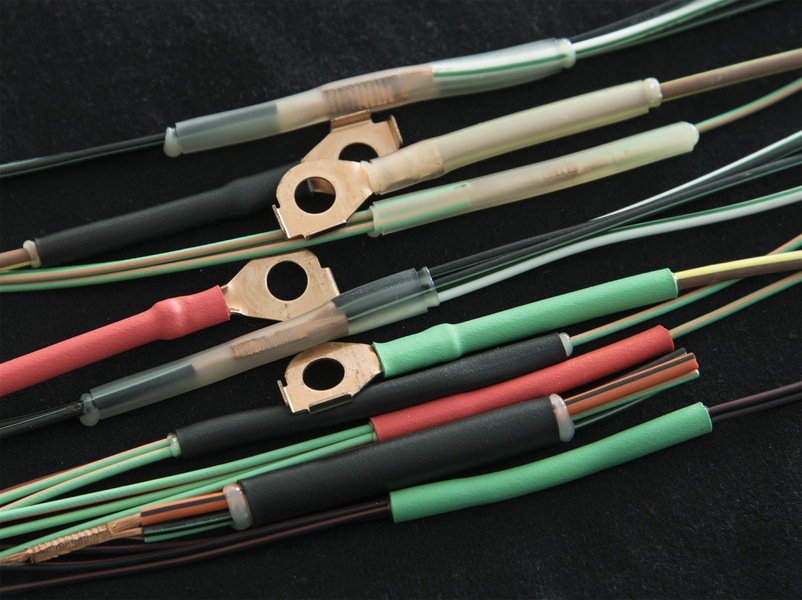

The correct way to use heat shrink tubing is very wide. We can see it in many industries. It has many advantages, such as good waterproof performance and relatively high viscosity. If you are using it for the first time, you often don’t know the correct way to use it. Let’s learn more abount it in detail below.

What is the correct way to use heat shrink tubing?

1. When using, you can use alcohol lamps, industrial hot air guns, compressed air and other methods to heat, so that the effect of uniform heating and shrinkage can be achieved.

2. If you need to achieve a relatively large amount of shrinkage, you can use boiling, steam heating, oven, etc. In addition, you can also use drying rooms, shrinking machines and other tools to heat the material, and the effect will be better. good.

3. It is very simple to use. Under normal circumstances, it only needs to be set and heated. For example, when we use it in daily life, we only need to put it on the object that needs to be repaired, and then use hot air to heat it. However, we need to be careful not to choose a heat shrinkable tube that is too thick when we put it on. Material, and there is no need to put tape inside, otherwise it will be sperfluous. Also, be careful not to let the wire ends pierce the heat shrink tube. You can check whether it is necessary to cover it with another layer according to the specific situation.

4. When heating, you can also directly use a lighter to heat. We can light the lighter and then put it in the flame. The flame will sway back and forth along the axis of the tube for a few seconds.

Some common questions about heat shrink tubing.

1. Features: It is made of polyolefin heat shrinkable sleeve. Generally speaking, it will shrink when heated to 125°C , and it has good softness and elasticity.

2. Material: The most common materials are PE, PVC, PET, ABS, EVA, etc.

3. Function: It is more commonly used in the packaging of batteries, electronics, inductance components, electrical appliances and other materials, which has a good insulation effect. When using it, we can use a shrink machine or hot air blower to make the heat shrink tube Crunch outer Cladding. You can directly put the heat shrink tube on the busbar in advance, wait until all the components are installed, and then tighten the screws. What you need to do next is to lay the heat shrink tube flat and use hot air to heat it. Very good on the busbar.

In short, heat shrinkable tubes must be used correctly. Only in this way can the performance be maximized and serve us better.

Powered by Froala Editor

Powered by Froala Editor