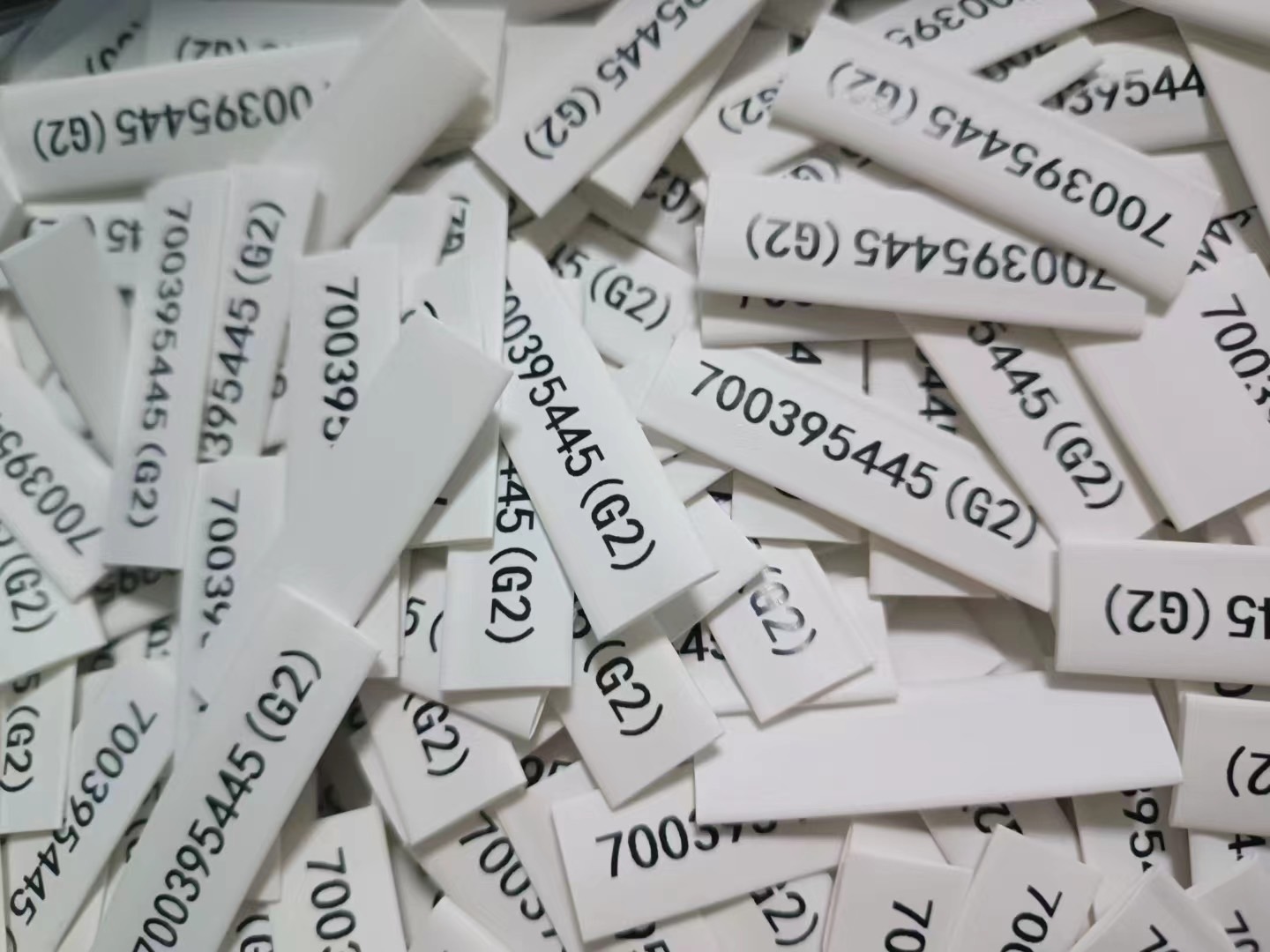

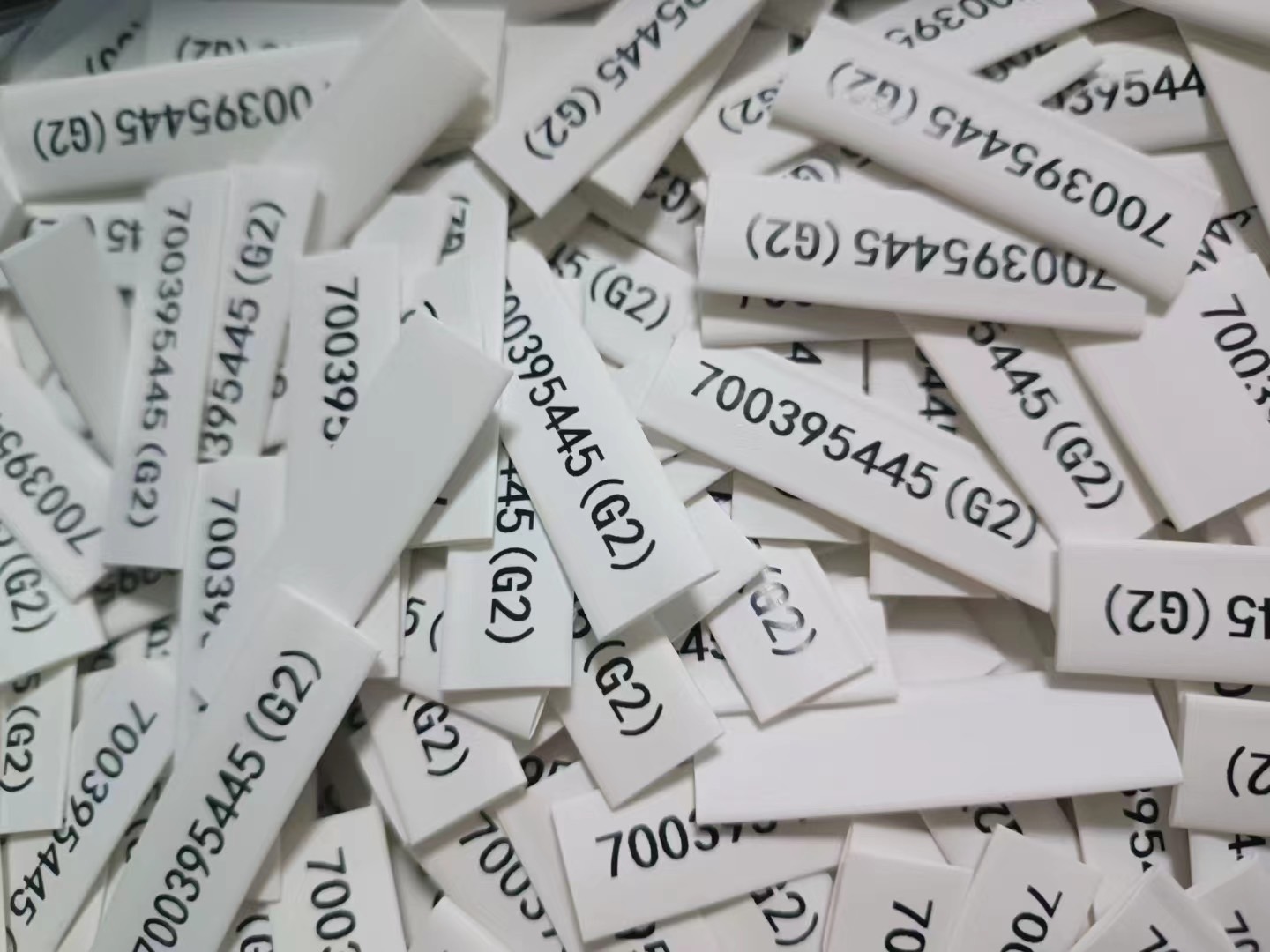

Halogen Free Heat Shrinkable Polyolefin

Designed to meet the requirement of high performance identification of wire and cable. Made from superior flame retardant polyolefin with outstanding properties. Durable printing and widely used in industrial, military, aerospace.

Powered by Froala Editor

FEATURES

Shrink ratio: 3:1, 2:1

- Flexible, Halogen-free flame-retardant.

- Easy to be printed.

- Excellent printing property, permanent identification,

- SAE AS81531 applicable.

- Excellent electrical, physical, chemical and printing properties.

- RoHS and REACH compliant.

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

TYPICAL APPLICATIONS

Material: polyolefin

- Operating temperature: -55˚C~125˚C

- Minimum shrink temperature: 70˚C

- Maximum fully recovery temperature: 110˚C

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

TECHNICAL DATA

Part No. | Dimension before shrinkage (mm) | Dimension before shrinkage (mm) | Standard Length (M) | ||

Diameter (D) | Thickness (T) | Diameter (d) | Thickness (t) | ||

MTHF1252X | |||||

MTHF1252X-0024 | ≥2.4 | 0.27±0.05 | ≤1.2 | 0.51±0.08 | 100 |

MTHF1252X-0032 | ≥3.2 | 0.27±0.05 | ≤1.6 | 0.51±0.08 | 100 |

MTHF1252X-0048 | ≥4.8 | 0.27±0.05 | ≤2.4 | 0.51±0.08 | 100 |

MTHF1252X-0064 | ≥6.4 | 0.32±0.06 | ≤3.2 | 0.64±0.08 | 100 |

MTHF1252X-0095 | ≥9.5 | 0.32±0.06 | ≤4.8 | 0.64±0.08 | 100 |

MTHF1252X-0127 | ≥12.7 | 0.32±0.06 | ≤6.4 | 0.64±0.08 | 100 |

MTHF1252X-0191 | ≥19.1 | 0.36±0.06 | ≤9.5 | 0.76±0.08 | 100 |

MTHF1252X-0254 | ≥25.4 | 0.45±0.08 | ≤12.7 | 0.89±0.08 | 100 |

MTHF1252X-0381 | ≥38.1 | 0.50±0.08 | ≤19.1 | 1.02±0.15 | 100 |

MTHF1252X-0508 | ≥50.8 | 0.58±0.08 | ≤25.4 | 1.14±0.08 | 50 |

MTHF1253X | |||||

MTHF1253X-0024 | ≥2.4 | 0.22±0.05 | ≤0.8 | 0.53±0.08 | 100 |

MTHF1253X-0032 | ≥3.2 | 0.22±0.05 | ≤1.1 | 0.58±0.08 | 100 |

MTHF1253X-0048 | ≥4.8 | 0.22±0.05 | ≤1.6 | 0.58±0.08 | 100 |

MTHF1253X-0064 | ≥6.4 | 0.22±0.05 | ≤2.1 | 0.58±0.08 | 100 |

MTHF1253X-0095 | ≥9.5 | 0.20±0.05 | ≤3.2 | 0.61±0.08 | 100 |

MTHF1253X-0127 | ≥12.7 | 0.20±0.05 | ≤4.2 | 0.61±0.08 | 100 |

MTHF1253X-0191 | ≥19.1 | 0.20±0.05 | ≤6.4 | 0.61±0.08 | 100 |

MTHF1253X-0254 | ≥25.4 | 0.20±0.05 | ≤8.5 | 0.64±0.08 | 100 |

MTHF1253X-0381 | ≥38.1 | 0.30±0.06 | ≤12.7 | 1.00±0.15 | 100 |

MTHF1253X-0508 | ≥50.8 | 0.30±0.06 | ≤17.0 | 1.00±0.18 | 50 |

Powered by Froala Editor

DIMENSIONS

Property | Test Method | Typical Value |

Tensile strength | SAE-AMS-DTL-23053 | ≥10.3MPa |

Elongation at break | SAE-AMS-DTL-23053 | ≥200% |

Low temperature flexibility | SAE-AMS-DTL-23053.4.6.7 | -55℃±1℃,4h,No cracks |

Hot Shock | SAE-AMS-DTL-23053.4.6.8 | 250℃±3℃,4h,No cracks, No dripping, No flow |

Aging properties | SAE-AMS-DTL-23053.4.6.9 | 75℃±2℃,168h No damage (visually intuitive damage) |

Tensile strength after aging | SAE-AMS-DTL-23053.4.6.13AndASTM D638 | ≥6.9MPa,23℃±2℃ |

Elongation at break after aging | SAE-AMS-DTL-23053.4.6.13和ASTM D638 | ≥100%,23℃±2℃ |

Color stability | SAE-AMS-DTL-23053.4.6.15 | 175℃±2℃,24h,by |

Dielectric strength | SAE-AMS-DTL-23053.4.6.13AndASTM D2671 | ≥19.7kV/mm,23℃±2℃ |

Volume resistivity | SAE-AMS-DTL-23053.4.6.13AndASTM D876 | ≥1.0x1014Ω· cm,500V(DC),60s |

Flame retardant | SAE-AMS-DTL-23053.4.6.14 ASTM D2671 UL224 | Self-extinguishing within 60s, more than 25% of the iconic flag is damaged or burned, no dripping and a large area falling |

Antibody solution performance | AE-AMS-DTL-23053.4.6.11 | No damage (visually intuitive damage) |

Printing durability | SAE-AS-81531.4.6.2 | Eraser 50 times, the writing is clearly visible |

Printing solvent resistance | MIL-STD-202G Method 215K | Eraser 10 times, the writing is clearly visible |

Powered by Froala Editor