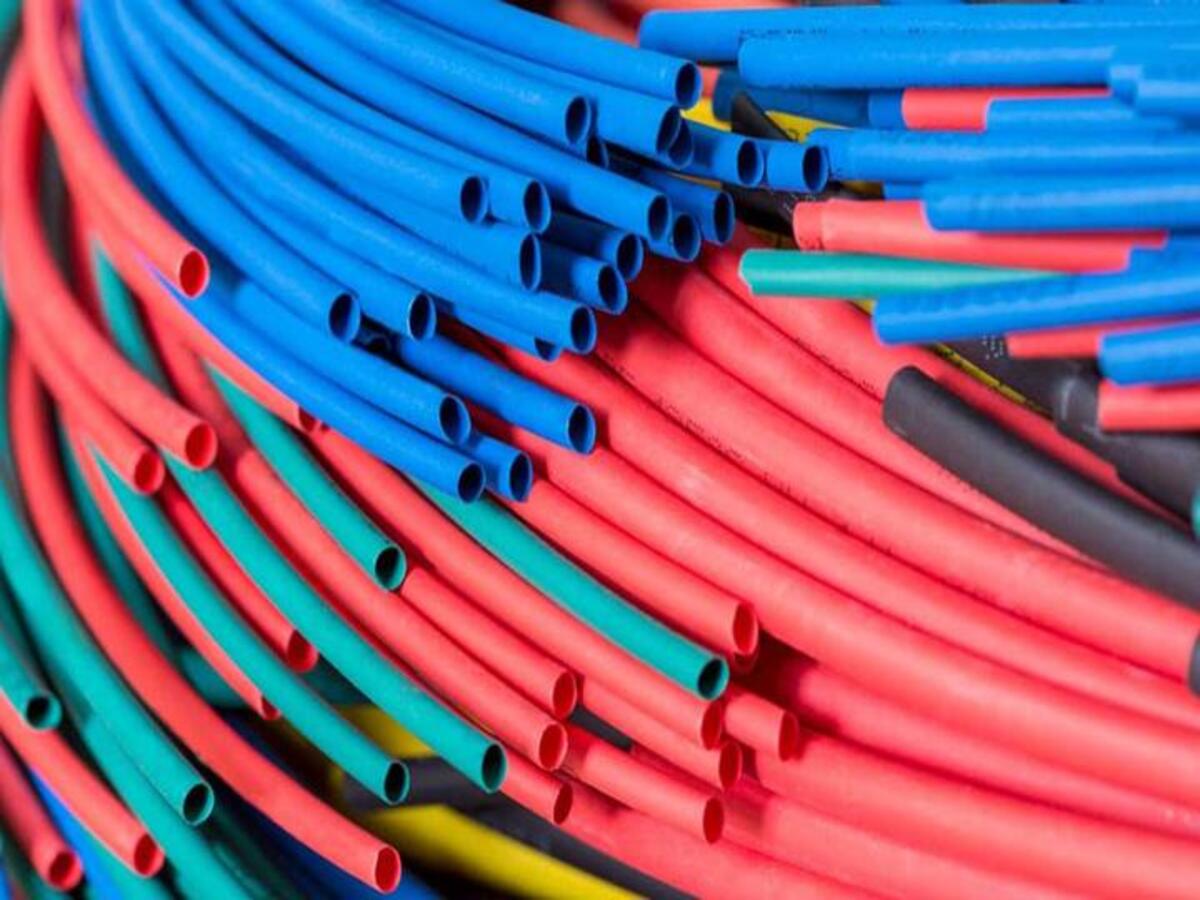

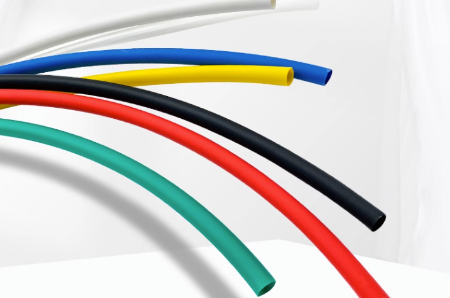

How to construct heat shrinkable tubes? These aspects must be considered carefully

The construction environment temperature of heat shrinkable tubes is usually between minus 20 degrees and 60 degrees. However, it should be noted that if the working environment temperature is lower than 0 degrees Celsius, insulation measures need to be taken. Be sure to make connections when making connections. Pay attention to follow the prescribed process, and consider the following aspects during construction.

1. Carefully check whether the docking end faces on both sides waiting for takeover are flat enough. It is required that the local gap after the two end faces are closed must be smaller than six millimeters. If this requirement is not met, it is not allowed and must be carried out. Adjust until the requirements are met.

2. Elevate the ends of the two pipes to be connected to create a certain distance between them and the ground. We have to judge the distance ourselves based on the actual situation. As long as the heating tool is more convenient to operate in the circumferential direction, it is ok.

3. What you need to do next is to put the heat shrink tube on one end of the two pipes to be connected, and then keep a distance of 500 milimeters. This is to be careful not to let the protective paper inside wear out. It must be complete. In this way, some impurities and dust will it during later use.

4. When polishing, the distance between the two pipes to be connected is 120 mm long from the butt end face. When polishing, it should be at least three and a half sections long. We also need to pay attention to the specifications. Different specifications depend on the size of the wire brush. It's also different.

5. Then weld the heat shrinkable tube with a PE welding rod that fuses with the connected tube, It is better if the welding seamcan be longer, and the temperature needs to be controlled at about 40°C -50°C .

6. The fiber heat shrink tape needs to be wrapped around the connection, and then the two ends of the pipe to be connected should be preheated in the polishing line. The temperature is the same as the above steps, and must be between 40°C -50°C . We can Use supervision.

Finally, carefully move the heat shrink tube to the polished surface at one end. The specific moving position is probably the distance from the initial heating to the butt end face, which is 1/3 of the entire heat shrink tube , and then put the upper layer after removing the protective paper, be careful not to allow some impurities to contaminate the inner wall of the heat shrink tube, otherwise it will cause trouble when we use it later. We must better ensure its shrinkage uniformity and surface smoothness.

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor